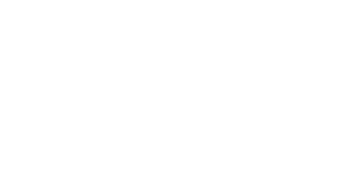

With an illustrious career spanning over five decades, Mr. Thomas P. Murphy, Jr. has not only shaped the skyline of Florida but has been at the forefront of transformative projects that have redefined the very essence of construction. As the Co-Founder of RENCO, he brings a wealth of experience and expertise to the table. Notable projects, including the Ocean Reef Club, The Surf Club/Four Seasons, and the Ritz Carlton SoBe, stand testament to his commitment to excellence.

This year, RENCO’s groundbreaking work in construction design has been recognized with the prestigious Construction Product Design of the Year. In this exclusive interview, we delve into Mr. Murphy’s remarkable journey, exploring the milestones that have shaped his career and the innovative ethos that propels RENCO to the forefront of the industry.

Join us to explore his design philosophy, strategic vision, and the driving force behind RENCO’s innovative approach to construction and design.

Can you tell us a bit about your background?

I started my career in construction more than 50 years ago while attending the University of Miami. I became the youngest person in Florida’s history to earn my contractor’s license at the age of 19. By the time I was 20, I started my own company, which eventually became Seaboard Construction, and sold it to Turner Construction Company almost 20 years later.

Growing restless, in 1988, I founded Coastal Construction on the principles of Best in Class Quality, Integrity and Transparency, with the goal of becoming “The Most Preferred Contractor in Florida.” Today, Coastal Construction is one of the leading general contractors in Florida, with more than $4 billion in active commercial and residential projects.

After more than five decades of being a builder, I’m now on a mission to revolutionize the construction industry. With RENCO, we are introducing a whole new way to build that’s faster, stronger, more sustainable and more affordable than traditional methods.

What was the inspiration or philosophy behind the RENCO? How did you get the idea of developing a new type of structural building system?

For the past century, the construction industry hasn’t really changed much, and I knew that innovation was lacking. Structures were only designed and built using wood, concrete, or steel. With RENCO, we were able to look at a new material that has a much smaller environmental impact, which is important to me.

As we see the industry facing historic supply chain issues, labor shortages and record-high material prices, we’re even more interested in bringing out a simpler and more sustainable way to build.

I teamed up with some of the brightest minds in the construction industry. Together, we have more than 100 years of experience and have built more than $10 billion in structures. We had a wealth of knowledge and a strong belief that we could shape the future of building.

What makes the RENCO so different from other building systems?

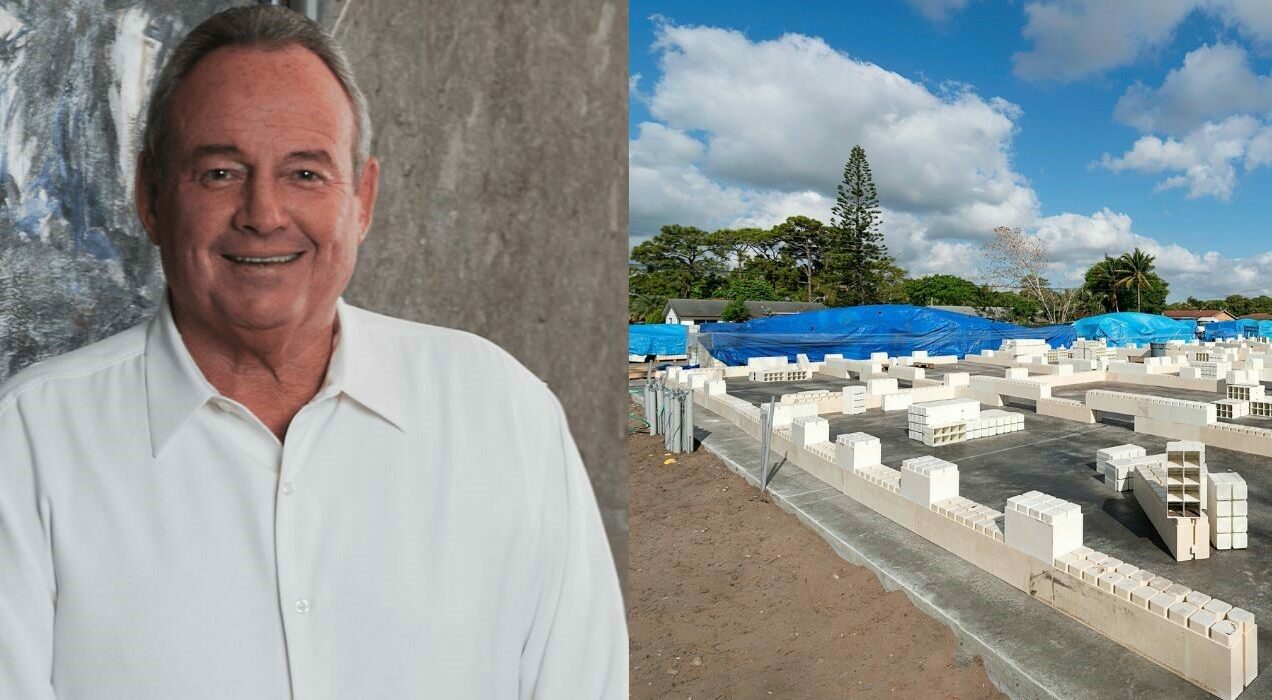

What makes RENCO stand out is its simplicity- basically real-life LEGOs, but they’re far stronger and more durable. The building industry hasn’t seen anything like this before.

RENCO uses a simple interlocking system, which accelerates the rate of construction. Instead of taking years to build large developments, we can now finish projects in months.

RENCO is short for “renewable composites,” and it uses a composite material that blends stone, recycled glass, recycled plastic, and resin. It performs better than traditional building materials with wind, seismic, water, and termites, and it’s a fraction of the weight.

Our building system can be customized to almost any design – top to bottom—from joists to the roof, to blocks for the walls, to decking for the floors. A small crew with no specialized training then quickly assembles the building using color-coded plans with just a mallet and glue gun.

As the construction industry faces a labor shortage of more than a half-million workers, RENCO is an innovative solution. Because it’s easy to assemble with color-coded plans, it opens us up to an entirely new labor market and can encourage more people to get into construction to offset the shortage of workers. Not only that, but its higher speed and lower cost mean developers can build more affordable housing, more quickly.

Another issue facing the construction industry is the increase of devastating storms. As a native Floridian, I’ve seen the destruction from hurricanes firsthand, and I believe we can innovate to make a difference. RENCO is a solution because it’s more durable, faster, and less expensive than concrete, wood, or steel. It’s also better for the environment; fully recyclable; and resistant to hurricanes, earthquakes, fire, pests, and mold. Because of these factors, RENCO structures are also easier to insure, which is essential as property insurance rates rise across the nation.

RENCO is currently approved to be used in Seismic Design Categories A and B, and you are currently researching further to become approved in the Seismic Design Categories C and D. What do you feel would be the next step for the RENCO Structural Building System?

We are expecting to achieve C, D, and E by the end of 2023. The next step for RENCO is also getting approvals to build up to eight stories.

Such an intricate and logistical project must come with its challenges. Can you share with us some of the biggest difficulties you’ve encountered while creating RENCO?

One of the greatest challenges facing RENCO is “change” itself and this mindset within the construction industry that we should just keep doing things the same old way. That’s why we took more than a decade to develop the system and bring it to market. It’s completed more than 400 tests in labs across the country to achieve approval for use under the International Building Code.

We believe that by changing how we build, we can make homes stronger, more affordable, and more sustainable. As natural disasters worsen and property insurance rates skyrocket, now is the time to innovate so we can create homes that can withstand storms and are easier to insure. And as America faces a housing affordability crisis, RENCO offers a solution to make building more affordable so that more people can achieve the dream of homeownership.

In which way does the RENCO system align with sustainable construction practices? What procedures did you take to minimize its environmental impact?

RENCO is an entirely new way to build apartments, offices, and homes without the massive carbon footprint of concrete. Concrete, which is bound together by cement, is a huge source of carbon emissions. In fact, more than 4 billion tons of cement were produced in 2021, contributing 8% of global CO2 emissions, according to the think tank Chatham House.

RENCO uses absolutely no concrete or cement. This is revolutionary and a breakthrough in green construction! Made of recycled materials, RENCO is a patented renewable composite material, made of stone, recycled glass, recycled plastic, and resin.

Because these materials are woven together in a mesh, it’s more flexible and extremely strong- withstanding wind tests in excess of 275 mph. To give an example, think of a bulletproof vest made of Kevlar, another type of synthetic material bonded together. Instead of trying to resist and stop a bullet, Kevlar flexes under impact, but doesn’t break, and it’s much lighter than a steel shield.

RENCO is kind of like a bulletproof vest in storms. It catches the impact but doesn’t shatter. Concrete on the other hand is rigid, and hard, so when it absorbs impact it’s more prone to cracking- especially in seismic events.

Building stronger structures will help reduce our carbon footprint by making homes that last for generations, especially as we face intensifying storms and impacts from climate change. RENCO is rated to last 100+ years, reducing the need to rebuild as often, and RENCO material can even be recycled and reused again.

The reality is that the building and construction sector sector’s greenhouse gas (GHG) emissions account for approximately 40% of global GHG emissions. The major contributors to these emissions are the materials used as well as the heating, cooling, and lighting of buildings and infrastructure. A Deloitte report found that using recyclable materials and building resilience against the environmental consequences of climate change are key steps to reducing construction’s carbon footprint. By using recycled materials and increasing building strength, RENCO accomplishes both of these sustainability goals.

What’s next for RENCO USA?

In South Florida, we are cutting the ribbon on the first RENCO housing development, a four-building, 96-unit complex in Palm Beach County. The first tenants have already moved in, and we’re proud to see its success.

We have completed scores of projects internationally and are proud to finish our first stateside project to demonstrate our many advantages over wood, concrete and steel construction, all while being respectful of our surroundings.

Our next step is opening our factory next year, so we can start producing blocks and materials for new sales orders. This will officially launch the expansion of RENCO, allowing more builders to access the technology.

Congratulations on winning the Construction Product Design of the Year prize at the BLT Awards! How does it feel to be recognized for your hard work?

Devoting more than five decades to the construction industry, my entire career has been driven by the pursuit of making a lasting impact. As a builder, I am particularly humbled and honored to receive the award for a new innovative building material. To me it’s not just about business; it’s personal. Winning this award is particularly gratifying because we are setting out to shape the future of construction to make it more sustainable and affordable. This will impact and benefit generations to come.

Which advice would you give to aspiring architects who want to make a significant impact in the field?

First and foremost, I would like to say that I have a strong appreciation for architects and I was honored to have the opportunity to name the University of Miami’s school of architecture after my father.

Architects set the vision for what we build. However, I think it’s important to know that more important than the structures you will build are the relationships you’ll make along the way. To create the best projects, you’ve got to work with the best people. Take care of your team and the people you work with. Commit to excellence and success will follow.